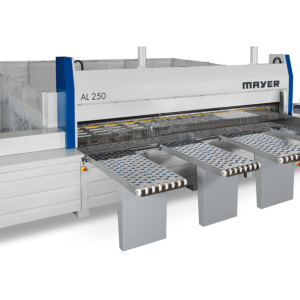

Description

- Cutting length of the longitudinal saw: 3200–9000 mm

- Cutting length of the crosscut saw: 1200–3200 mm

- Motor power: 18–75 kW

- Saw blade diameter: 450–860 mm

- Cutting height: 120–260 mm

Mayer angular systems stand for:

- Precise, reliable process control result in maximum capacity in the cutting process.

- Maximum availability through high-quality German engineering.

- Finish cut quality and maximum availability thanks to the latest sawing technology in heavy industrial design

- Concepts for every performance range with package heights up to 260 mm and sawing capacities up to 75 kW.

- Latest control technology with standard components and open systems.

- Adapted handling equipment for all panel products.

- Each system is tailored to our customers and their requirements.